ENTT-03 Gas

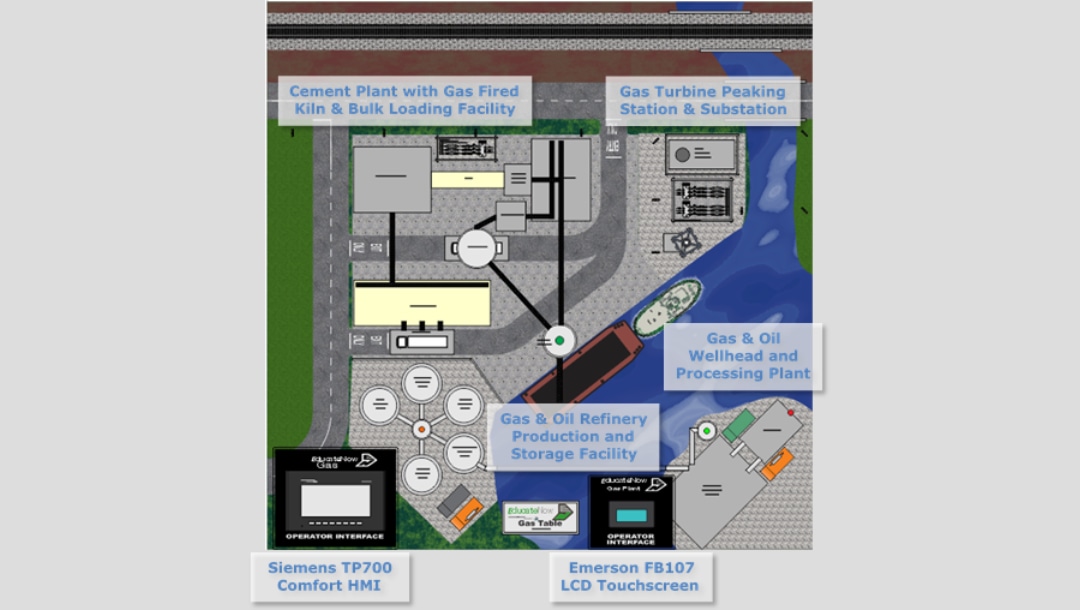

The EducateNow ENTT-03-Gas Training Table utilises common industrial control equipment to provide realistic interactive 3D models and simulations of common gas infrastructure systems such as gas and oil wellhead and processing plants, gas and oil refinery production & storage facilities for diesel, petrol, aviation fuel and town gas, gas turbine electrical peaking station, as cement plant with a gas fired kiln & bulk loading facility. This table is partway through the design and development phase with the construction and implementation of the first table planned for 2022.

Systems and functionality on this table includes:

- a Gas and Oil wellhead and processing plant

- a Gas & Oil Refinery Production & Storage Facility for diesel, petrol, aviation fuel and town gas

- a Gas turbine peaking station

- a Cement Plant with Gas Fired Kiln & Bulk Loading Facility with 1 axis rotation

- Sub-surface Integrated Status LED light strips for indication of underground water, gas and other production processes & statuses

- Sub-surface Integrated Status LED Rings for Tank capacities, Cement Kiln and Mill rotation as well as pump process indications

- Small Fans for various Cement Plant processes and a servo motor with associated limit sensors (aside from the encoder) for the Bulk Loader tower

- Small motors and associated limit sensors for the Container Gantry Crane X-Y-Z axes

The EducateNow ENTT-03-Gas Training Table will come with the following software and control programs;

- Emerson FB107 RTU control program interfaced with LCD touchscreen and wireless HART sensors

- Siemens 3010C RTU control program

- Siemens S7 300 PLC control program programmed in Step 7 classic

- Siemens S7 1500 Safety PLC control program interfaced with ProfiNet manual selector switch, push buttons and SICK rotary encoder

- Siemens S7 1200 Safety PLC control program interfaced with ProfiSafe Emergency Stop & manual push buttons

- Siemens TP700 HMI programming with control, status alarms and trending pages for the above Siemens PLCs

- Siemens WinCC Unified SCADA project with control, status alarms and trending pages for the above control equipment.

- Table Control PLC program for the control of the Mains Power, Water and Gas networks LED indication, interfacing with the Gas and Oil Well Head, Gas and Oil Refinery, Cement Plant and Gas Peaking power station and Sub Station PLCs as well as other connected Training Table PLCs.

Clients: Research Centers & Universities

Category: Research & Education

Standard Equipment:

Clear fronted lockable Controls Cabinet

230VAC Power supplies

Emerson FB107 RTU and wireless HART sensors

Siemens 3010C RTU

Siemens S7 300 PLC

S71500 Safety PLC with ProfiNet manual selector switch & push buttons as well as SICK rotary encoder

Siemens S7 1200 Safety PLC with ProfiNet Safety Emergency Stop & manual push buttons equipment

Managed & unmanaged Industrial Ethernet Switches

Siemens TP700 7″ HMI touch screen

Emerson FB107 LCD touch screen

Standard Control Software:

Emerson FieldTools Software package

Siemens Hart SIMATIC PDM

Viator HART Interface

SIMATIC WinCC Unified Engineering and Runtime and Operating licenses

Siemens Programming Field PG M6 Industrial Notebook with all commonly used interfaces for industrial applications, preinstalled with licenses for:

STEP 7 Professional Combo including TIA Portal

WinCC Advanced Combo including TIA Portal

Safety Advanced Combo including TIA Portal